-

-

January 30, 2018 at 4:14 am

peteroznewman

SubscriberRochester Institute of Technology Clean Snowmobile Team is an ANSYS sponsored team using Forte to predict engine emissions. RIT obtained the solid geometry from the engine manufacturer as a SOLIDWORKS (SW) file. I volunteered to help with geometry preparation to extract the fluid domain and partition the surfaces to make it ready for import into Forte.

Eric Oswald is a fifth year Mechanical Engineering student who is doing the Forte simulations.

Both DesignModeler (DM) and SpaceClaim (SC) can do the Fill operation to create a solid model of the fluid domain, but an important difference was revealed. DesignModeler and SOLIDWORKS both use the Parasolid geometry modeling kernel, while SpaceClaim uses the ACIS kernel. That means moving data from SW to DM is just a write and read operation, while moving data from SW to SC is a write, read and translate operation. Most of the time, this translation between the two kernels has no effect, but sometimes it causes a problem.

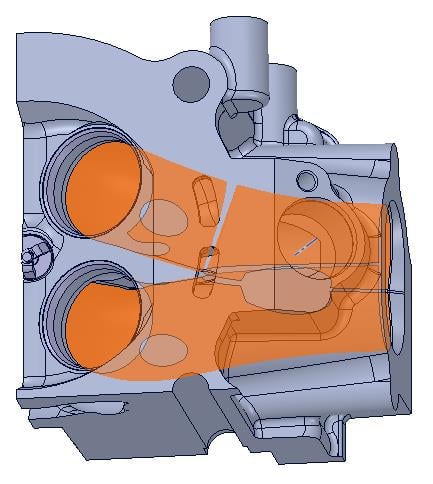

Below is the image of the inlet port as seen in DM and it looks the same in SW.

Here is the image of the inlet port as seen in SC. Note the spike defect just right of center.

In this case, I decided to use DesignModer to complete the geometry preparation!

-

January 30, 2018 at 7:55 am

vganore

Ansys EmployeeInteresting story Peter. Is it difficult to fix the defect in SC or we can't fix it?

-

January 30, 2018 at 12:04 pm

-

March 15, 2018 at 6:50 am

-

May 14, 2018 at 4:49 pm

Fernando Torres

SubscriberHy Sir peter ! Great explanation.

But instead of 3d modelling , if we are dealing with 2d i.e. want to import a 2d sketch to mechanical from another software , do we have to use "CONCEPT , SURFACES FROM SKETCHES" each time for large sketches ? For example if I am an AutoCAD fan of 2d modelling , and import a complex 2d sketch into DM , do I have to make surfaces by CONCEPT"SURFACES FROM SKETCHES" every time?

-

May 14, 2018 at 6:29 pm

peteroznewman

SubscriberCan AutoCAD create a bounded surface in the 2D drawing environment, or only lines and curves? If it can create surfaces, then you may be able to import and mesh directly on them. If you can't create surfaces, then you have to make surfaces in DM (or SC).

-

June 26, 2018 at 9:07 pm

FrankD

Ansys EmployeePeter and Vishal

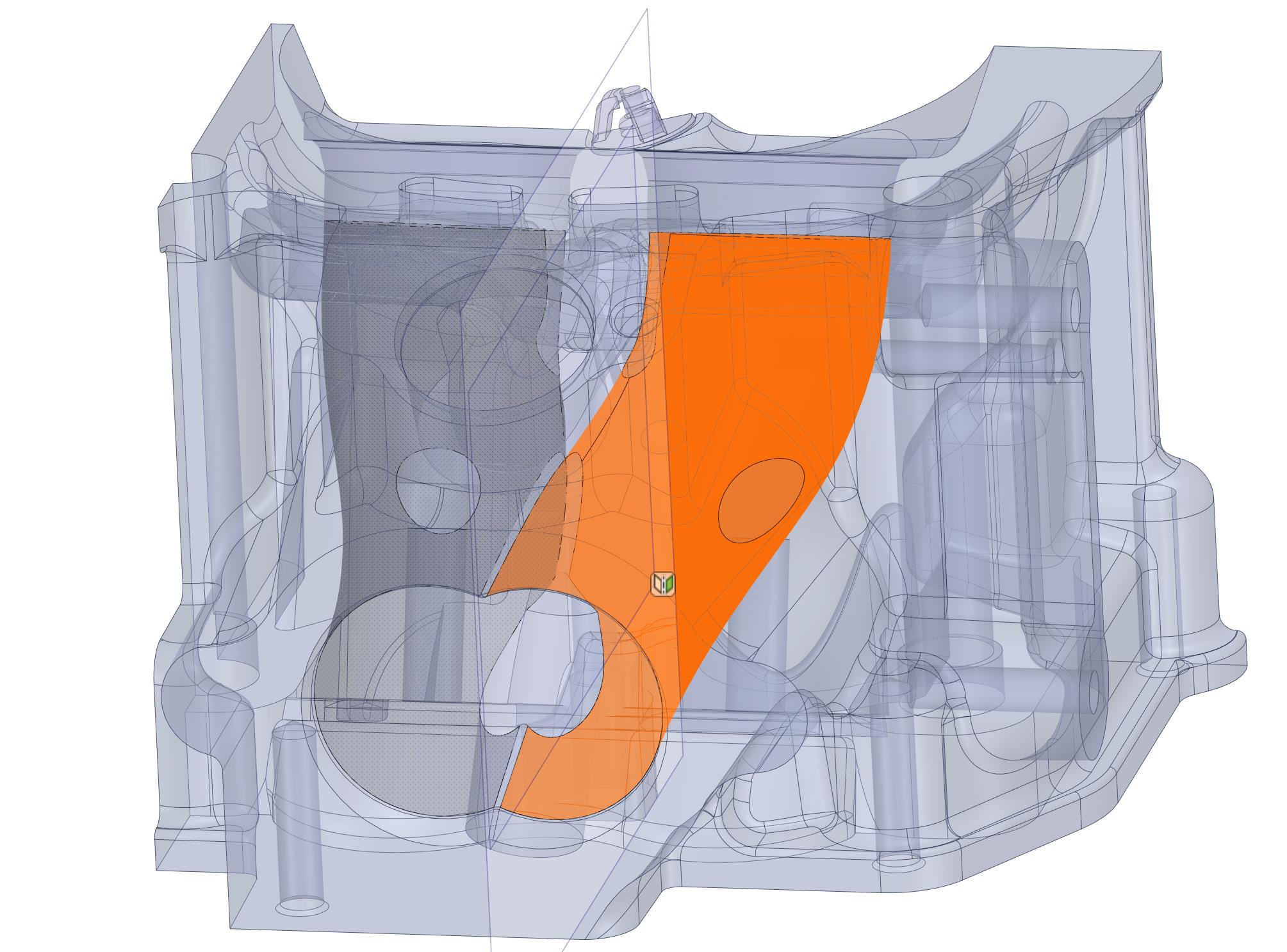

I appreciate the example -- translation is to be avoided if possible. However, I like to think that there is always a way to repair geometry, and strictly following the Repair tools is not always going to be the way to go. In this case, when you have geometry that is apparently 'all bad' like this, your only recourse is to delete the offending faces and get them in there somehow, again. You can recreate them, but in this case we got lucky because the intent of the part appears to be symmetry; and the other tube of the manifold looks good.

I made a temporary plane through the axis of what seemed like the center hole between the inlets (outlets?) and copy-pasted the good surface and mirrored it about the plane. They looked like a perfect match, to me. Then delete the bad face (there was just one) to turn the whole model to surfaces, as you can see above. The first try didn't choose the right side of these little nubbin surfaces (or perhaps I forgot to select them, see how they appear to float inside, unconnected to anything):

But a simple undo (to before the deletion,) copy-paste both nubbins (6 total faces,) do the delete again, and select the 4 surfaces to Merge in Combine, and you are done:

Back to solid part.

F

-

September 12, 2019 at 12:18 pm

sma4t

SubscriberThanks for the interesting topic. I Thought the SCDM would "always" be the way to go. But it seems that's not always the case.

I wanted to share this pdf which shows similar cases where each software would be more suitable to use than the other.

https://www.epsilonfea.com/wp-content/uploads/sites/5/2015/11/ANSYS-SCDMV6.pdf -

September 15, 2019 at 1:13 pm

sma4t

Subscriber

Hi!

I was wondering if saving the SW file as .stp and then importing into SCDM would solve the issue? This technique is recommended by SC's help and saved me from troubles lots of times.

-

- You must be logged in to reply to this topic.

Boost Ansys Fluent Simulations with AWS

Computational Fluid Dynamics (CFD) helps engineers design products in which the flow of fluid components is a significant challenge. These different use cases often require large complex models to solve on a traditional workstation. Click here to join this event to learn how to leverage Ansys Fluids on the cloud, thanks to Ansys Gateway powered by AWS.

Earth Rescue – An Ansys Online Series

The climate crisis is here. But so is the human ingenuity to fight it. Earth Rescue reveals what visionary companies are doing today to engineer radical new ideas in the fight against climate change. Click here to watch the first episode.

Ansys Blog

Subscribe to the Ansys Blog to get great new content about the power of simulation delivered right to your email on a weekly basis. With content from Ansys experts, partners and customers you will learn about product development advances, thought leadership and trends and tips to better use Ansys tools. Sign up here.

- Limitations of ANSYS Student

- When DesignModeler is a better choice than SpaceClaim

- Off setting lines onto surfaces

- Rosette direction issue due to Geometry limits

- Applying Moments for the Revolute Joints in Explicit Dynamics

- Free ANSYS Research software for Student Competition Teams

- Meshing Problem in Explicit Dynamic-Roll Cage

- workbench

- Ansys Composite prepost analysis

- Analysis of composite parts in student competition

-

7272

-

4248

-

2899

-

1374

-

1322

© 2025 Copyright ANSYS, Inc. All rights reserved.