TAGGED: ansys-mechanical, mesh, mesh-generating, mesh-generation, meshing

-

-

November 8, 2018 at 7:17 pm

nikkmojay

Subscriber"The surface mesh is intersecting or close to intersecting, making it difficult to create a volume mesh. Please adjust the mesh size or adjust the geometry to fix the problem."

I am so close to getting this mesh done, only one part is failing. It was created in CREO Parametric and is a boundary blend. This is a ducted fan design with a pattern of a boundary blend for the blades. This error pops up for the originally blended blade only. When I look at the problematic geometry it is one element. What should I do to fix this element? I have no idea what is causing this or how to fix it.

-

November 9, 2018 at 1:24 am

Sandeep Medikonda

Ansys EmployeePlease post some a picture to help understand your problem.

-

November 12, 2018 at 7:12 am

kkanade

Ansys EmployeeUse right click on the error message and click go to object. I will show you problematic geometry. Please use virtual topology or change mesh settings or create some local mesh sizes on this problematic face.

If that does not help, please post some images to understand your problem.

-

November 25, 2020 at 1:50 pm

-

November 25, 2020 at 6:53 pm

peteroznewman

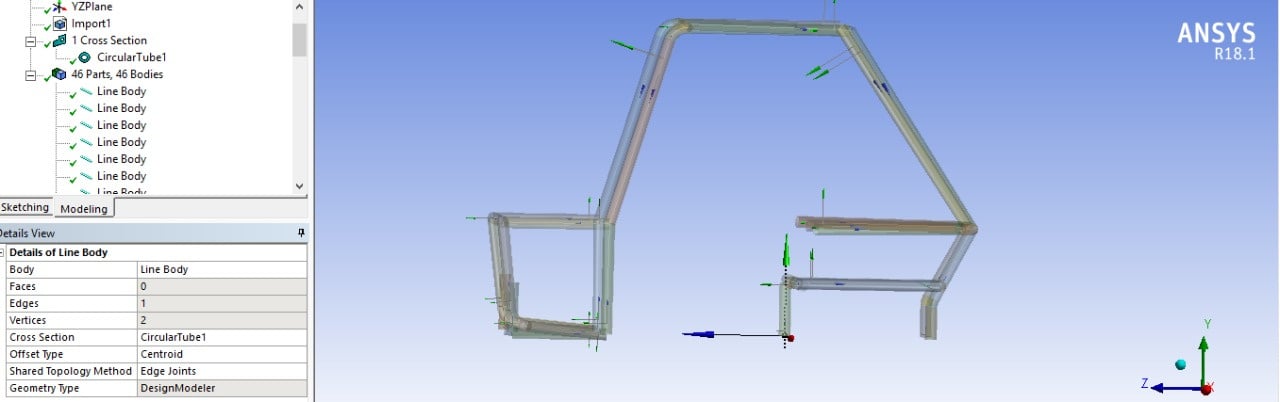

SubscribernI see you have solid bodies for the cart frame. This is not what you want to build a model because it will take too many elements to fill the solid bodies.nThere are two idealizations that result in reasonable number of elements in the model: shell elements and beam elements.nBeam elements result in the smallest model and is very easy to mesh and work with. The input geometry is the centerline of each tube. Make those centerlines meet at a common endpoint. The tube cross-section (OD and ID) are assigned to the beam element as a property of the element and those allow the FE model to compute the stiffness and stress in the elements.nHere is an example of a beam model: https://dev7.webdevonline.net/AIS/ais-multisite/forum/discussion/6689/solver-pivot-warning-in-beam-element-modelnShell elements result in a larger model that requires a bit more work. A midsurface of each tube must be created in CAD. Any gaps at the ends of tube midsuface to the next tube midsurface at joints have to be closed by editing the surface geometry or by using Bonded Contact in Mechanical. This is more work than the beam element model, but delivers more detailed stress results at the tube joints.nHere is an example of a shell model: https://dev7.webdevonline.net/AIS/ais-multisite/forum/discussion/1692/meshing-problem-in-explicit-dynamic-roll-cagen -

November 26, 2020 at 1:04 am

peteroznewman

Subscribern -

November 26, 2020 at 5:37 pm

KarthikShankar

SubscriberThanks Mr. Peter. I tried generating beam elements from line bodies (by assigning the cross sections,OD and ID).nBut I tend to lose some members of the chassis while importing the line body diagram into ansys. So, I coudn't proceed with the beam element method. Due to time constraints, I had to work with the solid body. nI designed it in solidworks.nExported as iges( line bodies- 3D curves-B-spline)n I have attached the picture (members missing).This is the state after assigning cross section.nCan you check it out.nThanksn

I have attached the picture (members missing).This is the state after assigning cross section.nCan you check it out.nThanksn

-

November 27, 2020 at 1:23 pm

peteroznewman

SubscribernLooks good so far. If you wanted to attach a file, you have to put that in a zip archive file first.n -

November 27, 2020 at 1:48 pm

KarthikShankar

SubscriberWhat should be the reason for members getting missed. What can I do?nShould I attach the component file?n -

November 28, 2020 at 3:00 am

peteroznewman

SubscribernConverting geometry between systems often has problems. You exported lines from SolidWorks to IGES. If you import that file back into SolidWorks, do you get all the lines?nDo you have SpaceClaim as well as DesignModeler? In SC, you can import solid geometry and convert them to beam. You can see if SC imports the IGES file better than DM.n

-

- You must be logged in to reply to this topic.

Boost Ansys Fluent Simulations with AWS

Computational Fluid Dynamics (CFD) helps engineers design products in which the flow of fluid components is a significant challenge. These different use cases often require large complex models to solve on a traditional workstation. Click here to join this event to learn how to leverage Ansys Fluids on the cloud, thanks to Ansys Gateway powered by AWS.

Earth Rescue – An Ansys Online Series

The climate crisis is here. But so is the human ingenuity to fight it. Earth Rescue reveals what visionary companies are doing today to engineer radical new ideas in the fight against climate change. Click here to watch the first episode.

Ansys Blog

Subscribe to the Ansys Blog to get great new content about the power of simulation delivered right to your email on a weekly basis. With content from Ansys experts, partners and customers you will learn about product development advances, thought leadership and trends and tips to better use Ansys tools. Sign up here.

- how to improve the inflation quality at sharp corners?

- ANSYS Workbench Measuring within Design

- check element type

- The mesh file exporter could not resolve cyclic dependencies in overlapping contact regions error

- Conformal vs Non-Conformal Mesh

- execution error inside the mesher. The process suffered an unhandled exception or ran out of memory

- Meshing Error

- Error in meshing

- inflation created stairstep mesh at some location

- How to resolve Mesh Failure

-

7272

-

4248

-

2899

-

1374

-

1322

© 2025 Copyright ANSYS, Inc. All rights reserved.